How Can I Prevent Spindle Bearing Damage?

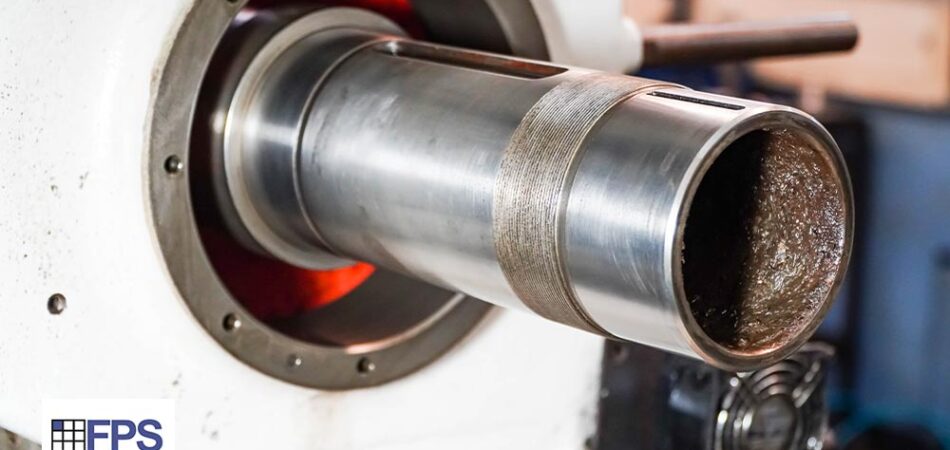

To keep your machine running optimally, you have to take good care of its heart: the spindle. When the spindle is healthy, you’ll suffer from less downtime and enjoy better overall performance. This requires properly applying spindle bearing lubricant and learning how to properly store and handle spindles. Here’s what you need to know to prevent spindle bearing damage.

Properly Applying Spindle Bearing Lubricant

Failure to properly lubricate woodworking or metalworking spindles can cause bearing failure. It results in unnecessary wear and tear, higher operating temperatures, and deterioration. Properly applying spindle bearing lubricant involves three key factors:

- The right type of lubricant: Applying just any type of lubricant won’t get the results you desire. You have to choose the right kind of lubricant. Look for the correct compatibility and viscosity for your machine and choose a quality product for optimal results.

- The right amount of lubricant: If you use too little lubricant, the bearings will get damaged. If you use too much lubricant, this can cause other issues with your machine. Always follow lubricant manufacturer specifications regarding the amount to apply.

- The right timing for lubricant: For best results, always adhere to a lubrication schedule. Even if you use the right type and the right amount, if you apply lubricant too frequently or not often enough, you can experience bearing failure.

How to Properly Store and Handle Spindles

Spindles and their components are more sensitive than many people realize. Tiny impacts can cause great damage. This makes it crucial to properly store and handle spindles. Use these tips to keep your spindles in top shape.

- Low humidity: Choose a storage area with low humidity so condensation does not accumulate.

- Consistent temperature: Avoid storing your spindles in a location that experiences drastic changes in temperature. The temperature should remain between 65 and 120° Fahrenheit.

- Stable environment: Always store spindles in an area with low vibration. This will protect the spindles so they can deliver top performance when you need them.

- Wrapping: While stored, consider wrapping spindles in oil paper. This will help keep the spindles healthy while not in use.

- Hand rotation: If spindles remain stationary for more than three months, the balls within the bearing can weld themselves to the raceway. To avoid this “micro-welding” effect, hand rotate the spindle by one to two revolutions every few weeks.

- Proper tools: When installing a spindle, it is essential to use the right tools to avoid damage to the spindle.

- Clean environment: In addition to using the right tools during installation, a clean environment is also key.

- Professional handling: For best results, leave all installation and handling of spindles to professionals.

What Tools Use Spindles?

Spindles are a combination of different parts that work together to generate the spindle tool and the machine that drives it. They include a rotating assembly that is powered by a motor that should be set to the optimal rpm (revolutions per minute) used to cut the material you are working with. If the speed is too fast, it may damage the material you are working with. On the other hand, if it is set to slow, the speed may not be fast enough to make the cuts needed, especially if you are working with hardwood or other materials that are denser in composition.

Spindles also have many smaller components, including:

-

- Angular contact bearings: determine the max RPM the spindle will have

- Drawbars: draws the tool holder up into the spindle taper

- Belleville washers: flat spring that keeps drawbar tension on the tool holder

- Pull studs: used by drawbar clamp to pull drawbar up to taper

- Drawbar clamps: locks the drawbar onto the pull stud

- Drive pulley: allows for the motor to rotate the spindle

We are Spindle Pros

At Fischer Precision Spindles, Inc., we know the ins and outs of modern woodworking and machine-tool spindles. We specialize in the sales and repair of a full range of brands and models, and our experts have been the trusted source for spindle services since 1985. Contact us today with any questions about properly applying spindle-bearing lubricant or for any assistance with storage and handling. Contact us today! Reach our team at 860-828-0595.